Product Description:

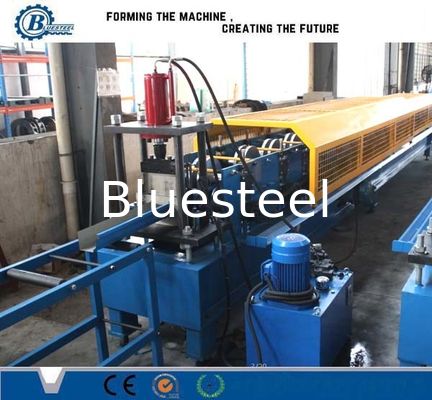

The Downpipe Roll Forming Machine is a high-performance machine specially designed for producing downpipes with a wide range of uses. It is equipped with a PLC control system, and features 45# steel as its roller and shaft material, 7.5kw as its main motor power, and a rolling thickness ranging from 0.3 to 0.8mm. This rain pipe forming machine is the ideal choice for efficient and precise production of downpipes in a short time.

The Downpipe Roll Forming Machine is reliable and efficient, providing users with a cost-effective and high-quality solution for producing downpipes. It is equipped with a PLC control system and features 45# steel as its roller and shaft material, 7.5kw as its main motor power, and a rolling thickness ranging from 0.3 to 0.8mm. The machine also boasts a high production speed and excellent pipe forming accuracy. All these features make this pipe forming machine an ideal choice for producing downpipes with utmost precision and speed.

The Downpipe Roll Forming Machine is a powerful and reliable machine designed for producing downpipes with utmost precision and speed. It is equipped with a PLC control system, and features 45# steel as its roller and shaft material, 7.5kw as its main motor power, and a rolling thickness ranging from 0.3 to 0.8mm. This rain pipe forming machine is the perfect choice for efficient and accurate production of downpipes in a short time.

Features:

- Product Name: Downpipe Roll Forming Machine

- Material of Roller: 45# Steel

- Control System: PLC

- Roller Stations: 13-18

- Diameter of Shaft: 80mm

- Drive Mode: Chain Drive

- Specialty: Down Pipe Forming Machine, Pipe Forming Machine, Rain Pipe Forming Machine

Technical Parameters:

| Parameter |

Value |

| Product Name |

Downpipe Roll Forming Machine |

| Forming Steps |

13-18 |

| Rolling Speed |

20-25m/min |

| Rolling Thickness |

0.3-0.8mm |

| Material of Shaft |

45# Steel |

| Power of Main Motor |

7.5kw |

| Material of Roller |

45# Steel |

| Power of Hydraulic Station |

3kw |

| Voltage |

380V/50Hz/3Phase |

| Weight |

4.5T |

Applications:

Downpipe Roll Forming Machine has been popularly used in many industries due to its remarkable features. Brand Name Banlu, Model Number BL-8, Place of Origin China, Hangzhou, Material of Shaft 45# Steel, Control System PLC, Rolling Width 200-300mm, Weight 4.5T, Voltage 380V/50Hz/3Phase is an ideal choice for pipe forming machine with great performance. It is a perfect combination of quality, reliability and efficiency.

The Downpipe Roll Forming Machine from Banlu is ideal for producing various types of pipes. It is equipped with a PLC control system that provides automatic and accurate control of pipe forming machine. The 45# Steel material of shaft ensures high-precision operation and long-term durability. This machine has a rolling width of 200-300mm and a weight of 4.5T. The voltage for the machine is 380V/50Hz/3Phase.

This downpipe roll forming machine is widely used in many industries, such as plumbing, construction, roofing, and automotive. It can be used for producing a wide variety of pipes, including round pipes, square pipes, rectangular pipes, and more. It is easy to operate and maintain and can produce pipes with high accuracy and efficiency. The machine is also cost-effective and provides great value for money.

The Downpipe Roll Forming Machine from Banlu is a reliable and efficient pipe forming machine with a high performance. It is designed to provide quality and reliability for a wide range of pipe forming applications. With its excellent features and reliable performance, this machine is an ideal choice for those who are looking for a cost-effective and reliable pipe forming machine.

Customization:

Customized Downpipe Roll Forming Machine from Banlu

Brand Name: Banlu

Model Number: BL-8

Place of Origin: China,hangzhou

Power of Main Motor: 7.5kw

Drive Mode: Chain Drive

Voltage: 380V/50Hz/3Phase

Control System: PLC

Product Name: Downpipe Roll Forming Machine

The customized downpipe roll forming machine from Banlu is perfect for rain pipe forming. With 7.5kw power of main motor, chain drive, 380V/50Hz/3Phase voltage, and PLC control system, you can rest assured that the machine is safe, reliable, and efficient.

Support and Services:

Technical Support & Services for Downpipe Roll Forming Machine

We provide a comprehensive range of technical support and services for Downpipe Roll Forming Machines, including installation, commissioning, training, maintenance and repairs.

Our highly trained engineers and technicians are available to assist customers with the installation, commissioning and training of their new Downpipe Roll Forming Machine.

Our team of experienced technicians are available for maintenance and repair services, as well as providing general advice and troubleshooting for any technical issues that may arise.

We are committed to providing the highest level of technical support and service for our customers, and are always available to answer any questions or provide assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!