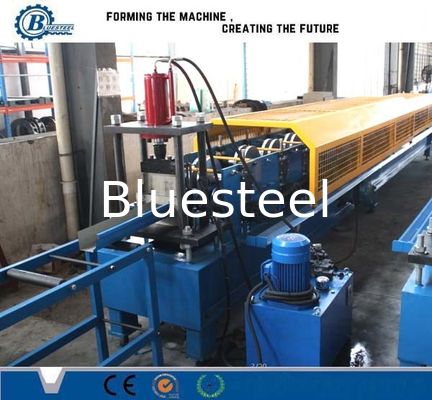

Product Description:

The Downpipe Roll Forming Machine is a pipe forming machine designed for the production of rain pipes. It has a wide range of applications and is suitable for industrial and residential buildings. With a rolling thickness of 0.3-0.8mm, a voltage of 380V/50Hz/3Phase, 13-18 roller stations, and a rolling speed of 20-25m/min, this machine is designed to increase productivity and efficiency in the production of rain pipes. It is also designed to be durable and reliable, providing consistent product quality and long-term performance. This pipe forming machine is a great choice for manufacturers who need a reliable and efficient machine for the production of rain pipes.

Features:

- Product Name: Downpipe Roll Forming Machine

- Drive Mode: Chain Drive

- Rolling Thickness: 0.3-0.8mm

- Roller Stations: 13-18

- Rolling Width: 200-300mm

- Power of Main Motor: 7.5kw

- Keywords: rain pipe forming machine, pipe forming machine

Technical Parameters:

| Parameter |

Value |

| Product Name |

Downpipe Roll Forming Machine |

| Rolling Thickness |

0.3-0.8mm |

| Rolling Width |

200-300mm |

| Voltage |

380V/50Hz/3Phase |

| Control System |

PLC |

| Material of Roller |

45# Steel |

| Roller Stations |

13-18 |

| Drive Mode |

Chain Drive |

| Rolling Speed |

20-25m/min |

| Material of Shaft |

45# Steel |

Applications:

Banlu BL-8 Downpipe Roll Forming Machine is designed and manufactured for the production of rain pipes. It is widely used in the manufacturing of rain pipes with rolling width of 200-300mm. The material of the rollers is 45# steel and the forming steps is 13-18. Banlu BL-8 Downpipe Roll Forming Machine is equipped with a PLC control system and the power of the main motor is 7.5kw. It is the perfect machine for producing rain pipes for different applications. With its robust design, high precision and reliable performance, it is the ideal choice for rain pipe forming machine.

Customization:

Customized Downpipe Roll Forming Machine

We offer a wide range of Downpipe Roll Forming Machines with features such as:

- Brand Name: Banlu

- Model Number: BL-8

- Place of Origin: China,hangzhou

- Roller Stations: 13-18

- Material of Roller: 45# Steel

- Power of Main Motor: 7.5kw

- Rolling Width: 200-300mm

- Product Name: Downpipe Roll Forming Machine

Our Downpipe Roll Forming Machines are perfect for producing pipe forms such as down pipe forming machine and pipe forming machine. Our machines are reliable, robust and easy to operate.

Support and Services:

Technical Support and Services for Downpipe Roll Forming Machine

We provide a comprehensive technical support and services for our Downpipe Roll Forming Machine. We have highly trained technicians to assist with installation, maintenance, and troubleshooting. We also provide technical training and customer service support.

Our technical support team is available to answer any questions you may have about the machine and its operations. We are always ready to provide the best solutions to help you get the most out of your Downpipe Roll Forming Machine. Our team will work with you to ensure that your machine is running efficiently and safely.

We provide a variety of services including preventative maintenance, parts replacement, upgrades, and troubleshooting. We are dedicated to providing the best customer service and technical support to ensure that your machine is running optimally. We are committed to providing a prompt and efficient response to all of your questions and concerns.

Our technical support and services are designed to help you maximize your machine's performance and keep it running in top condition. We are committed to providing the best service and support to ensure that your machine is running efficiently and safely.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!