Product Description:

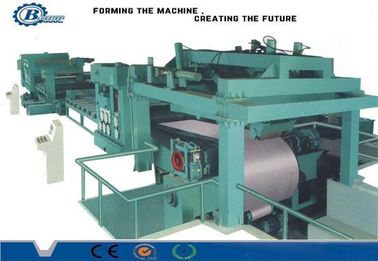

The Metal Slitting Line is capable of handling metal coils with a maximum weight of 25T and a width range of 200-2000mm. This machine is equipped with a coil loading car, decoiler, slitter, tensioner, recoiler, and coil unloading car, making it a complete automatic slitting line that can handle all aspects of metal slitting and shearing.

The Metal Slitting Line is designed with precision and accuracy in mind. It is equipped with advanced sensors and control systems that ensure the precise alignment and positioning of the metal coils during the slitting process. This ensures that the finished products are of the highest quality, with accurate dimensions and clean edges.

The Metal Slitting Line is also designed with safety in mind. It is equipped with safety guards and emergency stop buttons that ensure the safety of the operators during the metal slitting process. This makes it a safe and reliable choice for metal processing operations of all sizes.

The Metal Slitting Line is also versatile, with the ability to handle metal coils with a range of coil IDs, including 508mm and 610mm, and a maximum coil OD of 2000mm. This makes it a flexible choice for metal processing operations that require a wide range of coil sizes.

In summary, the Metal Slitting Line is an advanced and versatile automatic slitting line that is designed to provide efficient and precise metal slitting and shearing. With a maximum slitting speed of 120m/min, a maximum coil weight of 25T, a width range of 200-2000mm, and the ability to handle a range of coil sizes, this machine is an ideal choice for metal processing operations of all sizes.

Features:

- Product Name: Metal Slitting Line

- Width: 200-2000mm

- Power: 380V/50Hz/3Phase

- Slitting Accuracy: ±0.05mm

- Coil Weight: Max 25T

- Recoiler Weight: Max 25T

This product is an automatic slitting line used for metal slitting.

Technical Parameters:

| Technical Parameter |

Value |

| Product Name |

Metal Slitting Line |

| Slitting Accuracy |

±0.05mm |

| Coil OD |

Max 2000mm |

| Recoiler ID |

Max 610mm |

| Recoiler OD |

Max 2000mm |

| Thickness |

0.3-20mm |

| Coil ID |

508mm/610mm |

| Slitting Speed |

Max 120m/min |

| Dimension |

Customized |

| Width |

200-2000mm |

Applications:

The BL-9 Metal Slitting Line is designed to slit metal sheets with a width range of 200-2000mm and a thickness of 0.3-20mm, making it suitable for processing different types of metals such as steel, aluminum, copper, and zinc. This slitting line is perfect for use in industries such as automotive, construction, aerospace, and metal fabrication.

The Bluesteel Metal Slitting Line is manufactured in China and comes in customized dimensions to meet the specific needs of different customers. The machine's precision and accuracy are impressive, with a slitting accuracy of ±0.05mm, ensuring that the final product meets the required standards and specifications.

The BL-9 Metal Slitting Line features a recoiler ID of max 610mm, which makes it perfect for use in metal processing industries that require the production of smaller coils. This machine is also equipped with a high-speed slitting system, which improves productivity and efficiency while ensuring the quality of the final product.

The Bluesteel Metal Slitting Line is ideal for use in various product application scenarios such as the production of metal roofing sheets, metal pipes, and tubes. This machine can also be used in the production of metal packaging materials, metal furniture, and metal components for different industrial applications.

In conclusion, the Bluesteel Metal Slitting Line BL-9 is a reliable and efficient machine that can be used in various metal processing industries. Its exceptional features and specifications make it suitable for use in different product application occasions and scenarios, making it a valuable investment for any metal processing company.

Customization:

Packing and Shipping:

Product Packaging:

- The Metal Slitting Line product will be packed in a sturdy wooden crate to ensure safe transportation.

- The crate will be labeled with the product name and any necessary handling instructions.

- The product will be securely fastened inside the crate to prevent any damage during shipping.

Shipping:

- The Metal Slitting Line product will be shipped via a reliable shipping carrier.

- The shipping cost will be calculated based on the destination and weight of the package.

- The estimated delivery time will be provided to the customer.

- The customer will be notified with the tracking information once the product is shipped.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!