Product Description:

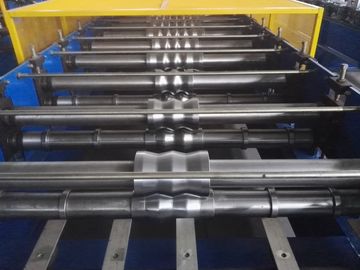

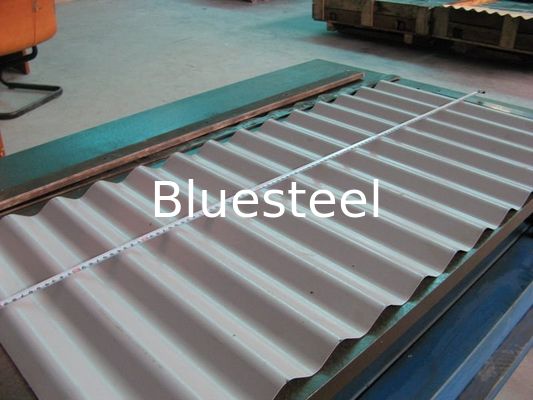

Our Corrugated Roll Forming Machine is a kind of steel roll forming machine specially designed for producing corrugated steel sheets. It is capable of producing corrugated steel sheets with width up to 1000mm, and its speed range is between 10-25m/min according to the actual needs of the users. The length of the sheets can be customized, and the roller stations are usually between 13-30. The power of the machine is 5.5kw. This versatile corrugated steel forming machine is ideal for producing quality corrugated steel sheets for various applications.

Features:

- Product Name: Corrugated Roll Forming Machine

- Control System: PLC

- Power: 5.5kw

- Type: Corrugated Roll Forming Machine

- Weight: 8T

- Roller Stations: 13-30

- Specialty: Corrugated Steel Forming Machine, Steel Roll Forming Machine

Technical Parameters:

| Parameter |

Value |

| Type |

Corrugated Roll Forming Machine |

| Power |

5.5kw |

| Speed |

10-25m/min |

| Weight |

8T |

| Material |

Steel |

| Thickness |

0.3-0.8mm |

| Length |

Customized |

| Control System |

PLC |

| Encoder |

Omron |

| Cutting Length |

Customized |

Applications:

BL-4 Corrugated Roll Forming Machine is a top-notch product of BL, which is a leading brand in China. This machine is made of steel and has a wide range of widths, from 1000mm to customised sizes. It features hydraulic cutting system, with a cutting accuracy of ±2mm. It is widely used for steel roll forming, corrugated steel forming and other applications. It is reliable and durable, which can serve you a long time.

Customization:

We provide customized service for Corrugated Roll Forming Machine with following attributes:

- Brand Name: BL

- Model Number: BL-4

- Place of Origin: China

- Cutting Length: Customized

- Weight: 8T

- Cutting Accuracy: ±2mm

- Roller Stations: 13-30

- Encoder: Omron

Our Corrugated Roll Forming Machine is specially designed for corrugated steel forming and is the best choice for you. It features top quality, competitive price and reliable performance. With our special steel roll forming machine, you can get great results of steel roll forming with high precision and efficiency.

Support and Services:

Corrugated Roll Forming Machine Technical Support and Service

We provide full technical support and service for our Corrugated Roll Forming Machine. Our experienced engineers are available to provide advice and guidance on the best machine for your needs, as well as troubleshooting any issues you may have.

We also offer a range of after-sales services including regular maintenance checks, emergency repairs and spare parts. We pride ourselves on offering a fast and efficient service, so you can rest assured that your machine will be up and running in no time.

Packing and Shipping:

Packaging and Shipping for Corrugation Roll Forming Machine

Before the Corrugation Roll Forming Machine is shipped, it is packaged securely and safely. The packaging includes a wooden crate for the machine, plus additional packaging to ensure the machine is not damaged during transportation.

The wooden crate is securely fastened with screws and bolts to protect against any shock or impact during shipping. The interior of the crate is lined with foam to protect the machine from any scratches or dents.

The Corrugation Roll Forming Machine is then loaded onto the truck or container for shipping. The truck or container is secured with straps and padding to prevent any movement while in transit.

The Corrugation Roll Forming Machine is shipped to the customer's specified location in the safest and most efficient manner possible.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!